Owner: Saline Water Conversion Corporation

Location: Shoaiba

Duration: June 2011 – May-2014

Contract Value: 222.4 Million Saudi Riyals

Scope of Work:

Plant rehabilitation, Re-Tubing & Venting system replacement to extend the plant life time for 15 years, 10 MSF units each of 22,280 M³/Day.

- Shoaiba Desalination & Power Plant Phase 1 was installed in 1988 at Saudi Arabia-Red Sea coast south of Jeddah city, comprising of 5 STG sets each of capacity 62 MW and 10 MSF units each of capacity 970 m3/hour.

- The 10 units of Multi-Stage Flash (MSF) Evaporator are cross tube type and are consisting of the followings:

- Heat recovery section, consists of 16 stages (Stage from 1 to 16) with 3957 tubes each stage. Brine Heater, with 3990 tubes and Top Brine Temperature of 90 ~ 110 oC.

- Heat rejection condenser section, consists of 3 stages (Stages from 17 to 19) with 2527 tubes each stage.

- The plant has been in service for the past 24 years. At present the tube failure exceeded the allowable limit of 5~10% of some stage due to accumulation of stagnant non-condensable gases at above demister area.

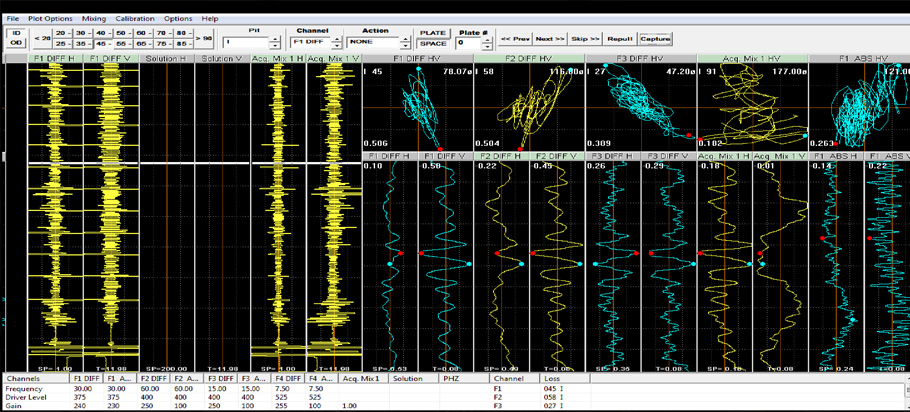

- The Scope of Works for rehabilitation of these units are to measure each tube thickness by Eddy Current Test (ECT) for (10) Desal units plus Brine heater. The total no. of tubes to be examined by ECT are around 700,000 tubes. Then replace the defective tubes of which tube thickness is less than 70% of the original thickness. The replaced defective tubes are around 230,000 pieces.

- Re-design venting system was completed in order to avoid accumulation of stagnant non-condensable gases to prevent/minimize future tube failures.

- The units had been handed over to SWCC after rehabilitations with the following excellent results:

- Distillate Water Output at 100% load is 975.3 m³/hour, against the origin design value 970 m³/hour.

- The Distillate Water Output at 120% load estimated to be 1,170 m³/hour, against the origin design value 1,164 m³/hour.

- The Distillate Water conductivity obtained is around 1.8 ~ 2.5 μs/cm, against the origin design value 50 μs/cm i.e. TDS at around 2 ppm. The Gain Output Ratio (GOR) at 120 % Load, (Kg distillate Per Kg condensate) is obtained to be 9.1 against the original design value 8.1.

- It is notice that the unit performance and production quantity after rehabilitation by partial tube replacement and stages venting system modification are increased above the original design figures.

- The result of Rehabilitation had shown increasing of the unit thermal efficiency over the original design by 10 % which save steam and fuel consumption.

- The expected lifetime extension for the plant after rehabilitation works is estimated to be more than 15 years under normal operation & maintenance condition

- As mentioned above this excellent result of rehabilitation works at Shoaiba Plant, Sasakura Middle East Company was highly appreciated and grated from the management of the client Saline Water Conversion Corporation.